+86-13376814803

+86-13376814803  robert@hzhongtai.com

robert@hzhongtai.com

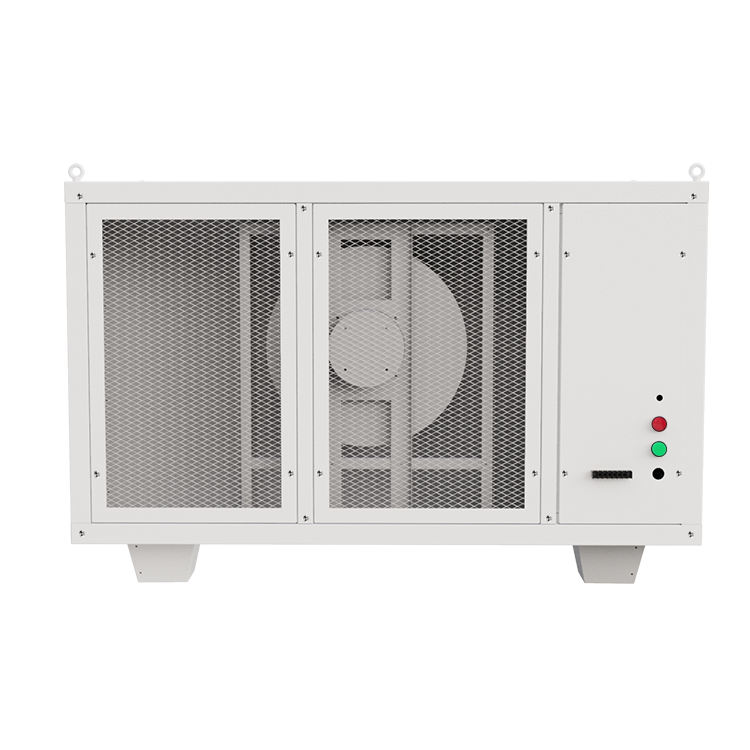

Industrial Dehumidifier For Sale

In the food industry, controlling humidity is crucial for maintaining product quality, preventing spoilage, and ensuring food safety. Large-capacity dehumidifiers play a significant role in creating optimal storage conditions for various food products. When selecting a dehumidifier for the food industry, consider the following features:

-

Capacity and Coverage:

- Choose an industrial dehumidifier with a capacity suitable for the size of the food storage area. Consider the volume of the space and the specific moisture removal needs of the products being stored.

-

Humidity Control:

- Opt for a dehumidifier with precise humidity control settings. Different food products may require specific humidity levels for optimal storage, and having control over this parameter is essential.

-

Energy Efficiency:

- Select an energy-efficient model to minimize operational costs. Energy efficient dehumidifiers can help reduce overall expenses in large-scale industrial settings.

-

Airflow and Distribution:

- Ensure that the dehumidifier has sufficient airflow and distribution capabilities to cover the entire storage facility. Proper air circulation is essential for maintaining consistent humidity levels.

-

Temperature Control:

- Some dehumidifiers come with integrated temperature control features. Maintaining the right temperature alongside humidity control is important for preserving the quality of food products.

-

Condensate Removal:

- Consider a dehumidifier with an effective condensate removal system. Options may include automatic drainage or the integration of pumps to handle large amounts of collected water.

-

Hygienic Design:

- Choose a dehumidifier with a design that meets food industry hygiene standards. Stainless steel or corrosion-resistant materials are often preferred for easy cleaning and to prevent contamination.

-

Air Filtration:

- Select a dehumidifier with high-quality air filtration systems to improve air quality within the storage facility. This is important for maintaining a clean environment and preventing the spread of contaminants.

-

Remote Monitoring and Control:

- If possible, choose a dehumidifier with remote monitoring and control capabilities. This allows for convenient monitoring and adjustment of humidity levels from a central location.

-

Maintenance Accessibility:

- Opt for a dehumidifier for food with easily accessible components for regular cleaning and maintenance. Regular upkeep is crucial for ensuring the longevity and efficiency of the unit.

-

Compliance with Food Safety Standards:

- Verify that the dehumidifier complies with relevant food safety standards and regulations. This ensures that the unit is suitable for use in food processing and storage areas.

-

Security Features:

- Consider security features such as tamper-resistant controls to prevent unauthorized access to the dehumidifier settings.

-

Integration with HVAC Systems:

- Some industrial dehumidifiers can be integrated into existing heating, ventilation, and air conditioning (HVAC) systems for enhanced control over environmental conditions.

-

Durability:

- In a demanding industrial environment, durability is key. Choose a dehumidifier with robust construction and components that can withstand the conditions of the food industry.

Before making a purchase, it's advisable to consult with experts in industrial dehumidification or food safety to ensure that the selected unit meets the specific needs and regulations of the food industry.

Related Products