+86-13376814803

+86-13376814803  robert@hzhongtai.com

robert@hzhongtai.com

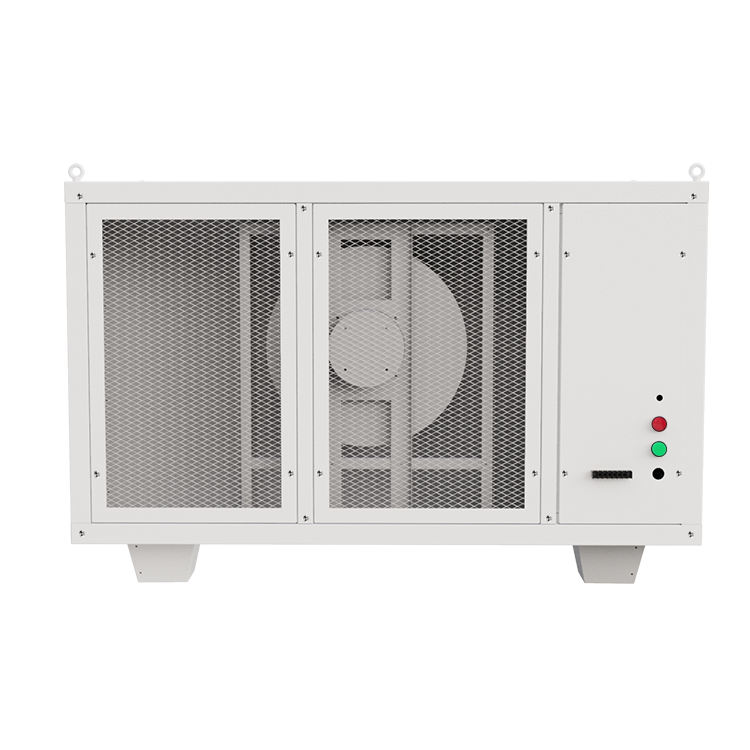

Industrial Dehumidifier Machine

Industrial dehumidifiers are heavy-duty machines designed to control and reduce humidity levels in large industrial spaces. These machines are commonly used in manufacturing facilities, warehouses, storage areas, and other industrial settings where maintaining the right humidity is crucial for the production process, product storage, and employee comfort. Here are some key features and aspects of industrial dehumidifier machines:

-

Capacity: Industrial dehumidifier machines come in a range of capacities to address the varying needs of different industrial environments. The capacity is usually measured in terms of the amount of moisture the unit can remove per day, often in pints or liters.

-

Dehumidification Technology: There are two primary types of dehumidification technologies used in industrial units: refrigeration-based and desiccant-based. Refrigeration-based dehumidifiers cool the air to condense and remove moisture, while desiccant-based units use a desiccant material to absorb moisture.

-

Installation Type: Industrial dehumidifiers can be portable, wall-mounted, or ceiling-mounted. The choice depends on the specific needs of the industrial space and the available installation options. Preair provides high-efficient ceiling dehumidifiers for sale.

-

Airflow and Ducting: Many industrial dehumidifiers come with options for ducted airflow. This allows for the distribution of dehumidified air throughout the facility, ensuring consistent moisture control.

-

Temperature Range: Consider the temperature range in the industrial environment. Some industrial dehumidifiers are designed to operate efficiently in both high and low-temperature conditions.

-

Construction and Durability: Industrial dehumidifiers are built with robust materials to withstand harsh industrial environments. They are often corrosion-resistant and durable to ensure longevity.

-

Control and Automation: Look for units with advanced control features such as digital displays, programmable settings, and built-in hygrometers. Automation features can help maintain the desired humidity levels without constant manual adjustments.

-

Energy Efficiency: Energy efficiency is crucial in industrial settings where large amounts of energy are consumed. Choose units with energy-efficient components and features to minimize operating costs.

-

Condensate Management: Industrial dehumidifiers generate condensate as a byproduct of the dehumidification process. Units typically come with options for drainage, including built-in pumps, gravity drainage, or external drainage systems.

-

Noise Level: Consider the noise level of the industrial dehumidifier, especially if it will be operating in areas where noise is a concern. Some units are designed for quiet operation.

-

Remote Monitoring and Control: Advanced dehumidifiers may offer remote monitoring and control capabilities. This can be useful for centralized control and monitoring of multiple units.

-

Compliance with Standards: Ensure that the industrial dehumidifier complies with relevant industry standards and safety regulations.

-

Warranty and Support: Consider the warranty offered by the manufacturer and the availability of customer support. A reliable warranty and support system are important for addressing issues and ensuring the longevity of the equipment.

-

Air Filtration: Some industrial dehumidifiers come with air filtration features to improve indoor air quality by capturing particles and contaminants.

Related Products